3D Printing Is Child's Play Featured Pattern: P0808 August 2015

Abstracts in this Pattern:

China's academic institutions appear to be attempting to teach the nation's next generation of workers the skills they need to work in tomorrow's economy. XYZ Printing (New Kinpo Group; Taipei, Taiwan) is involved in a project to distribute 3D printers to each of China's 400,000 primary schools. XYZ Printing will be among the largest suppliers of printers for the 3D-printing-education project, but other manufacturers will provide printers for the schools as well. Providing so many schools with 3D printers represents a strong commitment to 3D-printing technology and its potential future impact on the economy.

Governments are not alone in aiming to encourage kids to use 3D-printing technology. Mattel (El Segundo, California) and Autodesk (San Rafael, California) have announced a partnership to create and distribute applications that enable children to design and print their own toys. Children will not need a home 3D printer: A dedicated facility will 3D print children's designs and ship the toys to children's homes. Autodesk claims that the applications will debut with its new 3D printer in late 2015. Presumably, Autodesk will encourage parents to buy the 3D printer to provide their children with instant gratification; however, parents may order prints of their children's designs if they do not have the budget or space for a home 3D printer. Mattel may choose to use some of the designs that children create as inspiration for new products or accessories to its current toy lines.

Innovations that enable the use of a wider variety of materials in 3D-printing applications may also contribute to 3D printing's becoming more accessible to children. In collaboration with researchers from Cornell University (Ithaca, New York) and Carnegie Mellon University (Pittsburgh, Pennsylvania), Disney Research (The Walt Disney Company; Burbank, California) has developed a prototype of a new 3D-printing device that creates soft, bendable objects by layering laser-cut fabric. Instead of depositing layer after layer of plastic, the device laser cuts adhesive fabric, aligns the layers of fabric, and uses heat to bond the layers into a solid object. The device is experimental, and how Disney will use aspects of the technology to address the toy market is unclear at this point. But perhaps children eventually will have access to similar machines—or machines with similar functionalities—to create their own toys at home.

The Development of this Pattern

Data Points

- SC-2015-07-01-027

XYZ Printing is involved in a project to distribute 3D printers to each of China's 400,000 primary schools. - SC-2015-07-01-078

Mattel and Autodesk have announced a partnership to create and distribute applications that enable children to design and print their own toys. - SC-2015-07-01-104

In collaboration with researchers from Cornell University and Carnegie Mellon University, Disney Research has developed a prototype of a new 3D-printing device that creates soft, bendable objects by layering laser-cut fabric.

Implications

3D Printing Is Child's Play

Although 3D printing is a novel manufacturing process, its first widespread users may be children, not professionals.

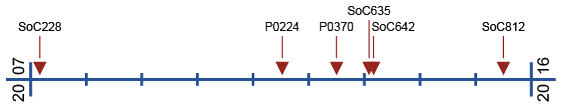

Previous Alerts

- SoC228 — The Personal Factory Redux (March 2007)

Futurists have long speculated about systems that allow the average consumer to print a physical object using affordable and easy-to-use computer-aided design software, laser scanners, and cheap materials. The technologies to enable such capabilities now appear to be coming together in ways that might be even more interesting and compelling than the experts imagined. - P0224 — 3D Print Your Own (July 2011)

Early in 2007, SoC228, "The Personal Factory Redux," pointed to the possibility of consumers' becoming more active in 3D-printing applications. Recent evidence suggests diffusion of the technology has begun. - P0370 — Digital Tangibles (July 2012)

The selection of cost-effective 3D-printing hardware is growing, and the sharing of digital instruction files for these printers could make the technology truly disruptive. - SoC635 — The Promises of 3D Printing (February 2013)

In 2012, 3D printing made headlines with advances in technology, application areas, business models, and commercialization. This Signal of Change outlines what changes 3D printing, or additive manufacturing, could introduce and how technological advances are setting the stage for these changes. - SoC642 — Adventures in Additive Manufacturing (March 2013)

This Signal of Change provides an overview of conceptually proven additive-manufacturing applications such as constructing buildings, creating biological material for medical uses, and even manufacturing meat and food for human consumption. Commercial use of these applications is speculative, but some of the approaches will likely prove disruptive in their respective arenas. - SoC812 — Road Maps for Consumer 3D Printing (July 2015)

The discussion also provides a possible road map for the introduction and diffusion of advanced 3D-printing technologies into end-consumer markets during the next ten years.