Advances in Metal 3D Printing Featured Pattern: P1183 March 2018

Abstracts in this Pattern:

In late 2017, General Electric's (GE's; Boston, Massachusetts) GE Additive division unveiled the first Beta metal 3D printer it developed as part of its Project A.T.L.A.S (Additive Technology Large Area System). The goal of this project is to develop large-format (on the order of meters) metal 3D printers for key industries, including the automotive and aerospace industries. GE Additive arose in part from GE's acquiring controlling shares of Concept Laser (Lichtenfels, Germany) and Arcam (Mölndal, Sweden), which are leaders in the metal-3D-printing space. GE is making use of 3D printing in some of its other divisions as well. For example, GE Healthcare has opened a 3D-printing lab in Sweden that focuses on medical products. The Innovative Design and Advanced Manufacturing Technology Center for Europe in Uppsala, Sweden, uses 3D printers, including metal 3D printers, with robots to augment traditional manufacturing techniques.

Desktop Metal (Burlington, Massachusetts) is commercializing an approach to metal 3D printing that could prove transformative. Current-generation metal 3D printers typically user laser-based techniques, but Desktop Metal's printers use an inkjet-like technology that places layers of metal powder on top of one another and "sprays layers of wax and a plastic binding agent in very specific patterns. The final printed part is then first placed in a 'debind' fluid that breaks down the wax and most of the plastic before being placed into a furnace where the rest of the binding agent...is burnt off, leaving just the metal." Desktop Metal claims that its technology enables metal 3D printing at a small fraction of the cost of competing technologies in a small fraction of the time. If the company's technology can deliver on these promises, it could compete not only with other metal-3D-printing technologies but also with some other types of current-generation manufacturing systems.

Another important differentiator in the 3D-printing space is the variety of materials that machines can print. For example, Desktop Metal's machines can print copper, titanium, and steels. Improving the quality and variety of 3D-printing materials is an active area of research. Researchers at the Lawrence Livermore National Laboratory (LLNL; Livermore, California) collaborated with researchers from other institutions to develop a new method of printing stainless steel that reportedly triples the strength of the steel and improves the steel's ductility.

The Development of this Pattern

Data Points

- SC-2018-02-07-046

In late 2017, General Electric's (GE's) GE Additive division unveiled the first Beta metal 3D printer it developed as part of its Project A.T.L.A.S (Additive Technology Large Area System). - SC-2018-02-07-078

Desktop Metal claims that its technology enables metal 3D printing at a small fraction of the cost of competing technologies in a small fraction of the time. - SC-2018-02-07-056

Researchers at the Lawrence Livermore National Laboratory collaborated with researchers from other institutions to develop a method of printing stainless steel that reportedly triples the strength of the steel and improves the steel's ductility.

Implications

Advances in Metal 3D Printing

Research in 3D printing metal is active, and new commercial developments exist.

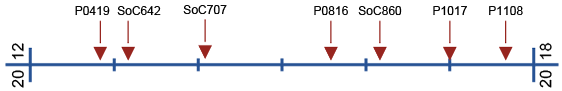

Previous Alerts

- P0419 — Extreme Printing (November 2012)

Advancing three-dimensional-printing technologies could not only address consumer markets but also enable some rather extreme applications. - SoC642 — Adventures in Additive Manufacturing (March 2013)

This Signal of Change provides an overview of conceptually proven additive-manufacturing applications such as constructing buildings, creating biological material for medical uses, and even manufacturing meat and food for human consumption. - SoC707 — Advancing Medical 3D Printing (February 2014)

Three-dimensional printing is particularly suited to many applications in health care and medicine because those areas often demand personalization. - P0816 — 3D Printing's Exotic Materials (August 2015)

Exotic and unusual materials are beginning to see use in 3D-printing applications. - SoC860 — 3D Technology and Tinkering (March 2016)

Companies should make use of the tinkerer and maker communities. - P1017 — Layering Capabilities (January 2017)

Researchers are using layering techniques and technologies to enable novel applications. - P1108 — A Wider Range of 3D-Printing Materials (September 2017)

The range of materials finding use in the 3D printing of objects is widening, establishing new 3D-printing applications.