Advancing Biological Manufacturing Featured Signal of Change: SoC1074 March 2019

As more biological products move toward the marketplace, companies are looking for methods that reduce the cost of biological manufacturing (biomanufacturing) without compromising product quality. Living-organism-based manufacturing technologies have the advantage of using low-toxicity materials, and biomanufacturing is typically more environmentally friendly than are traditional manufacturing methods. Living organisms and engineered microorganisms have substantial potential for use in many industries. Biomanufacturing often finds use in the production of biofuels for the energy industry, and it has already found use in the production of complex therapeutic agents. In addition, biomanufacturing could revolutionize the chemicals and materials industries by providing more efficient and environmentally friendly alternatives to manufacturing methods that use fossil-fuels feedstock. Furthermore, biomanufacturing could enable producers to control the materials or chemicals that they create at the small scale, potentially enabling improvements in the quality of products.

Enabling tools will be vital to the development and commercialization of engineered microorganisms for use in biomanufacturing.

Researchers at the University of British Columbia (Vancouver and Kelowna, Canada) genetically engineered Escherichia coli to overproduce lycopene—a dye that can perform photosynthesis. The researchers then coated the bacteria in a semiconductor material and applied it to a glass plate. This new method can produce biogenic solar cells that retain their efficiency even in dim light, and it does so without the use of toxic solvents and at about 10% of the cost of the dye-extraction method typically in use to make biogenic solar cells. The researchers expect that the efficiency of their hybrid solar cell could eventually match the efficiencies of conventional solar cells. Much additional work—for example, finding ways to keep the bacteria alive to produce the dye continuously and to increase the longevity of the solar cell—is necessary, but a new hybrid cell may be an important advance in enabling the development of sustainable high-efficiency cells that can see use in many applications.

Scientists at the Massachusetts Institute of Technology (Cambridge, Massachusetts) created a swallowable bacteria-on-a-chip sensor. The sensor contains genetically engineered bacteria that can diagnose gastrointestinal bleeding and other gastrointestinal conditions. The ultra-low-power electronic chip converts the bacterial response into a wireless signal that researchers can read on a smartphone. Although the device will likely find use in medical applications, a wide range of applications should be able to benefit from such a combination of biological and electronic sensors.

Engineered microorganisms that produce chemicals can show very positive results in the laboratory; however, large-scale fermentation processes expose microorganisms to toxins and stresses that can cause them to evolve and stop producing the chemicals that researchers engineered them to produce. To overcome this problem, researchers at the Novo Nordisk Foundation Center for Biosustainability (Technical University of Denmark; Kongens Lyngby, Denmark) genetically engineered Escherichia coli bacteria that produce mevalonate—a precursor for the manufacture of certain pharmaceuticals—to reduce their growth rate when mevalonate production levels decreased and to slow their evolutionary changes enough for the bioproduction to meet industrial standards. The research could aid in making the bioproduction of chemicals scalable to industrial levels and has implications for the chemicals, materials, and pharmaceuticals industries. Researchers at the Fraunhofer Institute for Interfacial Engineering and Biotechnology (Fraunhofer Society for the Advancement of Applied Research; Munich, Germany) use fungi to produce a variety of chemicals—including detergents, emulsifiers, and active ingredients for cosmetics, pharmaceuticals, and pesticides—at an industrial scale. Fungal biomanufacturing offers many benefits to manufacturers because it enables them to use a variety of metabolic pathways, to convert a wide range of renewable raw materials, and to produce a plethora of products that can find use in a wide range of applications.

Although bacteria and fungi are common sources in bioprocessing, algal and other cells produce a range of unusual metabolites that researchers have exploited to a much more limited extent. Algae offer many benefits as a source of biofuels: They can grow on nonarable land rather than on valuable cropland, and they can use saltwater rather than freshwater. Algae farming could use much less land than soy and corn farming currently do, and the algae could use waste carbon dioxide to grow. Many researchers have long seen algae-based biofuels as the most scalable and environmentally beneficial type of biofuel. But in combination, the high costs of algae biofuels and the low costs of petroleum fuels forced many developers to give up on algae biofuels and shift their focus to higher-value chemicals and products. Exxon Mobil Corporation (Irving, Texas) is among the developers that still plan to produce algae biofuels at an industrial scale. The company plans to use a highly productive algae strain that it developed with Synthetic Genomics (La Jolla, California) to produce 10,000 barrels a day of algae-based biofuel. Exxon Mobil is already talking about achieving the production of hundreds of thousands of barrels of the algae biofuel per day. Such biofuels would fit well with the company's existing hydrocarbon products and fuel infrastructures.

Because microalgae photosynthesize and use carbon dioxide, employing microalgae to produce a hydrocarbon could effectively be a carbon-neutral process. However, concerns exist about the environmental and commercial sustainability of algae-biofuel production. Researchers must overcome several challenges before the use of microalgae to produce chemicals at an industrial scale can become viable. Researchers at the University of Konstanz (Konstanz, Germany) developed a two-step, one-pot process to use the fivefold unsaturated fatty acid eicosapentaenoic acid (a component of microalgae oils) to produce benzene, which is a natural component of crude oil and a precursor to the production of various complex chemicals.

Enabling tools will be vital to the development and commercialization of engineered microorganisms for use in biomanufacturing; however, legislation and guidelines may need to change for biomanufacturing-enabling technologies to reach their full potential. In addition, scientists may need to overcome several factors that limit the advance of biomanufacturing systems. Typical limiting factors include a lengthy and complex process of product discovery and development, the cost inefficiency of transporting materials to the treatment site in areas with poor supply chains, the low availability of suitable processes for scaling up biomanufacturing processes, and the high cost of constructing a bioreactor. Developers may need to find business models that work for the potentially disruptive technologies they are developing. In addition, companies need to be aware of potential liability issues that relate to the accidental release of modified organisms. The field of synthetic biology, which includes the creation of synthetic genomes, may provide useful lessons.

The Development of this Signal of Change

Data Points

- SC-2018-10-03-020

Researchers at the University of British Columbia genetically engineered Escherichia coli to overproduce lycopene—a dye that can perform photosynthesis. - SC-2019-02-06-024

Researchers at the Fraunhofer Institute for Interfacial Engineering and Biotechnology use fungi to produce a variety of chemicals—including detergents, emulsifiers, and active ingredients for cosmetics, pharmaceuticals, and pesticides—at an industrial scale. - SC-2018-05-02-053

Exxon Mobil Corporation is among the developers that still plan to produce algae biofuels at an industrial scale. The company plans to use a highly productive algae strain that it developed with Synthetic Genomics to produce 10,000 barrels a day of algae-based biofuel.

Implications

Advancing Biological Manufacturing

Living organisms and engineered microorganisms have substantial potential for use in many industries.

Previous Alerts

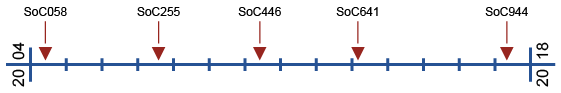

- SoC058 — Synthetic Biology (June 2004)

Advances in biotechnology are allowing researchers to create new life forms, genetically program existing life forms, and use life forms to manufacture hormones, metabolites, or drugs. - SoC255 — Bioprinting (August 2007)

The potential for bioprinting as a viable manufacturing alternative is creating considerable interest in several arenas beyond medicine. - SoC446 — Harnessing Living Materials (June 2010)

Researchers are now beginning to develop what could become an entirely new class of materials and technologies with dynamically adaptive properties by harnessing living organisms and biological materials. - SoC641 — Harnessing Nature (March 2013)

Biomimicry advocates working in materials science, agriculture, architecture, civil engineering, and other fields have borrowed directly from botanists, entomologists, and ecologists. - SoC944 — Exploring Biobased Materials (May 2017)

A growing number of companies are embracing the use of biobased materials in their products and even changing the types of biobased materials they use.